PLC Programming Training

Learn how to become a PLC programmer!

Last Updated: February 17, 2023

Find PLC Programmer Training Classes!

Find hands-on PLC programmer training courses to advance your career in the automation industry. We have some tremendous hands-on PLC training programs listed throughout the United States. PLC programmer training classes generally last multiple days, while other training courses may last several weeks or months.

The need for programmable logic control (PLC) programmers is rising, with industrial automation growing yearly and the manufacturing labor force in the United States decreases. Becoming a controls engineer or PLC programmer is a great career path that can benefit both the organization and the engineer. These courses are for those looking for a start in automation engineering or already in the field.

Many companies will provide PLC training to their employees to upskill within their organization. This upskilling allows organizations to grow their staff’s technical skills to fill the automation skill gaps. If your organization is looking for training facilities for automation engineers, controls engineers, or PLC programmers, our list of programs will be beneficial.

You can now find these PLC training classes all located in one spot. This article aims to help people find the best PLC programming training classes for each person’s specific requirements.

Who needs PLC programmer training?

- New PLC Programmers – Never used a controller before? No problem; sign up for a beginner PLC course, learn the basics of PLC programming, and start your PLC career!

- Current PLC Programmers – If you are in the automation industry and have never taken a training class, update your existing technical automation skills to know your current controller's ins and outs.

- Experienced PLC Programmers – Interested in learning how to program a new controller brand, or maybe your company is about to update existing PLC equipment? Learn how to use the controller before it gets to your facility.

- PLC Experts – Continue your education, and challenge your automation experience by learning something new about the controller system you did not know before.

Basic Types Of PLC Programmer Classes:

Listed below are the types of PLC classes training facilities will teach depending on the student's skill level.

- Beginner PLC Course – These PLC classes will teach introductory programming functions, including editing or modifying PLC programs, learning essential functions of the controller, and input or output signals. Students will also learn safety protocols and how to reset controller faults.

- Intermediate PLC Course – Create PLC programs from scratch, and create programmable ladder logic. Learn how to set up macros and properly use input/out functions.

- Advanced PLC Course – Advanced PLC training courses will specialize in critical areas of the automation process, either with specific tools and equipment with the process or on its key features.

What to look for in a PLC training class?

Hands-On PLC Programmer Training Courses.

Below we will describe our top robotics courses and schools for robot programmer training and why.

SKIP TO:

Automation Trainers

Approximate Course Cost: $3,000.00

Training Facility Highlights:

Student-to-PLC Ratio: 1:1

Controllers Available: 1

Controller Brands: Allen Bradley

Number of Classes Offered: 1

Average Class Size: 3 max.

Accredited: No

Provided Certification: Yes

Site Location: Shelby Twp., MI

Automation Trainers Courses:

PROS

- PLC-to-student ratio

- Small class size

- Postgraduate support program

- Great instructor

- 5-day class of 1 on 1 training

- Also have robot programming classes

CONS

- Only 1 controller is available

- Only Allen Bradley training is currently available

Advanced Automation Trainers (also known as Automation Trainers) is great for one-on-one PLC ladder logic learning. The smaller class size is structured to have the students be focused on the controller while getting lots of hands-on training. The control-to-student ratio is 1:1, allowing students to dive deep into learning the controller.

They offer a postgraduate PLC support program where students can reach out to the instructor after training to ask questions. A detailed learning packet is provided to each student for them to keep notes or highlight topics learned.

TW Controls

Approximate Course Cost: $2,980.00

Training Facility Highlights:

Student-to-PLC Ratio: 1:1

Controllers Available: 8

Controller Brands: Allen Bradley

Number of Classes Offered: 1

Average Class Size: 8 max.

Accredited: No

Provided Certification: No

Site Location: Roanoke, VA

TW Controls Courses:

PROS

- 5 days of training

- 1 student per workstation

- No lectures or PowerPoint slides

- Simulate real-world examples

- 100% money-back guarantee

- They also sell training equipment

- Informative training content across their social media platforms

CONS

- Only Allen Bradley training is available

- No catered lunches

This week-long training course is an intense course that will teach maintenance and electrical technicians how to troubleshoot and problem-solve with an Allen Bradley PLC. The class will cover Level 1 and Level 2 PLC for Studio 5000 / RsLogix 5000.

The staff at TW Controls is focused on providing 2-way dialog with students. They focus on providing learning opportunities for everyone in the class while not on getting through a certain number of lessons each day. These 5 long days will be worth your time and effort once you return to your facility and increase productivity by decreasing your downtime with plc ladder logic programming.

Think-PLC, LLC

Approximate Course Cost: $1,850.00

Training Facility Highlights:

Student-to-PLC Ratio: 1:1 or 2:1

Controllers Available: 12

Controller Brands: Siemens

Number of Classes Offered: 5

Average Class Size: 12 max.

Accredited: No

Provided Certification: Yes

Site Location: Lexington, NC or Kinsport, TN

Think-PLC, LLC Courses:

PROS

- Course price

- Customized PLC courses

- Train on-site with the customer’s equipment

- Students are given take-home materials.

- Use real-world automation examples during training

- Siemens solution partner

CONS

- Only focused on Siemens training.

Think-PLC provides hands-on instruction that can be course customized for your company. They can also schedule the training at your facility. Their consultants can also come to your facility to train staff when installing new automation equipment.

Their staff stays up-to-day with the latest automation technology and industry standards with their state-of-the-art training facility. They offer multiple types of Siemens automation classes focused on providing high-value services to their customers. Their courses provide lunch/snacks to maximize time in the classroom with the controllers.

Global Automation Training Solutions

Approximate Course Cost: -

Training Facility Highlights:

Student-to-PLC Ratio: -

Controllers Available: -

Controller Brands: Omron / Mitsubishi / Rockwell

Number of Classes Offered: 40

Average Class Size: 8 (4 min. / 12 max.)

Accredited: -

Provided Certification: -

Site Location: Seymour, TN

Global Automation Training Solutions Courses:

PROS

- 40 courses available

- 3 different types of controller training

- Larger class sizes

- On-site training available

- Customized training available

- Training available in multiple languages

- Online classes available

- Also have robotics classes

CONS

- Minimum class size of 4 students required a month before class.

Global Automation Training Solutions uses facility-trained instructors with decades of hands-on experience. Because of their knowledge, the instructors are able and willing to assist with questions that are outside of the scheduled curriculum. They offer many training classes with Omron Automation, Mitsubishi Electric, and Rockwell Automation controllers.

They can also train at a customer’s facility and customize that training to your request. Global Automation Training Solutions offers a free training evaluation and recommendations for each company’s specific PLC situation.

Automation Training, INC.

Approximate Course Cost: -

Training Facility Highlights:

Student-to-PLC Ratio: -

Controllers Available: -

Controller Brands: Allen Bradley

Number of Classes Offered: 29

Average Class Size: -

Accredited: -

Provided Certification: -

Site Location: Carmel, IN

Automation Training, INC. Courses:

PROS

- Lots of options for experienced PLC programmers to further their education

- Offer other general industrial training courses

- They provide Tech Notes from prior training courses

CONS

- Only Rockwell Automation classes

At Automation Training Inc. (ATI), they prioritize training students to perform at the best of their PLC abilities. They have instructors who have industrial PLC experience and can lead a practical PLC class. Automation Training Inc. can also provide training specific to your industrial application.

ATI's instructors are proven engineers with real-world work experience that they translate into classroom examples. Their instructors are established in the classroom setting, can handle adverse situations easily, and can be flexible with instructions to make them applicable to all PLC students in the classroom.

OEM PLC Training Courses:

Take a PLC programming course directly from an original equipment manufacturer (OEM). Check out these links to set up your training course at the controller manufacturer. The OEMs often have very detailed PLC training courses on their systems and are meant for customers who purchase their equipment directly.

PLC Programming College Courses:

Are you interested in continuing your automation education? These colleges and tech schools offer college-level PLC or PLC programming classes.

Cincinnati State | Cincinnati, OH

Programmable Logic Controller Certificate

This program is designed for individuals who install, program, maintain, or troubleshoot Programmable Logic Controllers (PLC) in an industrial setting. Students will gain a working knowledge of ladder logic and learn the basics of PLC programming. Students learn the fundamentals of PLCs, including processor configuration, digital output and input wiring, analog and digital concepts, and PLC program instructions. The advanced PLC class offers students advanced programming instructions and remote I/O, and it introduces advanced troubleshooting. This program focuses on Rockwell Software (RS Logic 500 & 5000) and Siemens PLC processors and programming.

Oakland Community College | Auburn Hills, MI

PLC & Robotics Technician Program

Advanced manufacturing is in high demand for industrial automation. OCC has a hands-on programmable logic controller and robotics technician training program that allows students to acquire the certifications needed to attain various jobs with manufacturers, system integrators, and factory automation-related fields.

LEARN MORE ABOUT PLC PROGRAMMING

PLC Programmer Salary:

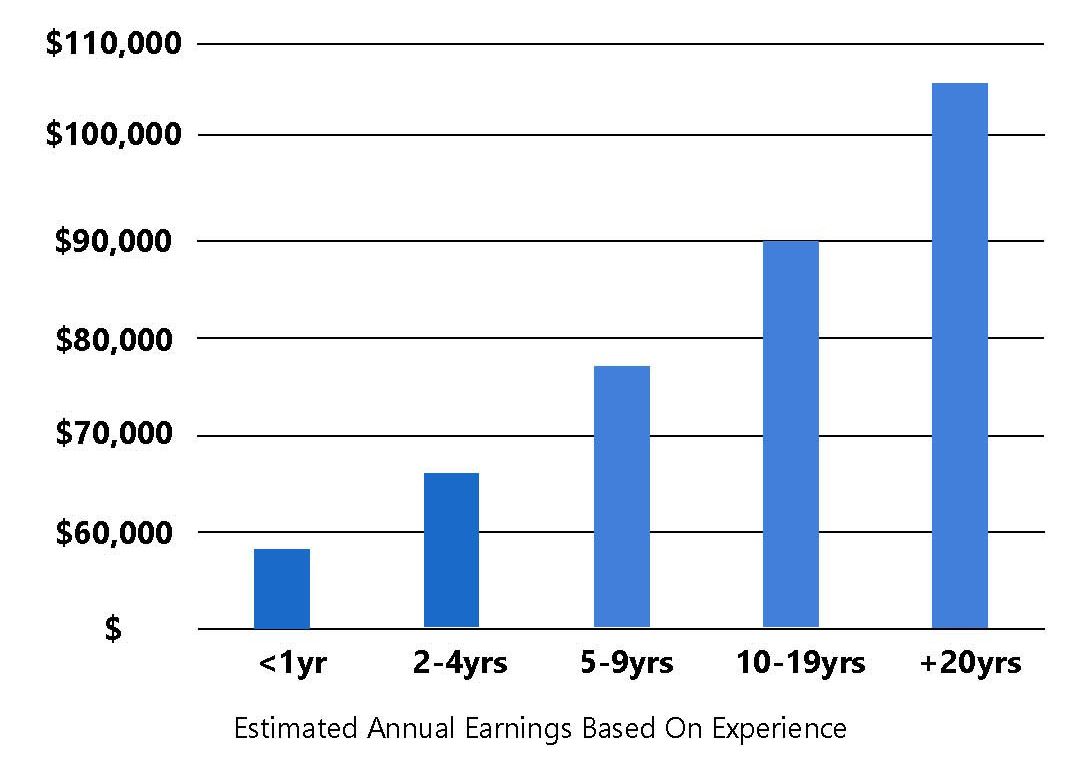

The average PLC programmer’s salary in the United States is around $72,000 annually. This pay range for a PLC programmer is approximately $38.30/ hour or over $6,600/month. The average PLC programmer’s salary can vary quite drastically depending on the location of the job, the programmer’s technical skill level, and prior PLC experience.

PLC Programmer Jobs:

There currently are lots of open PLC programmer jobs throughout the United States. Here is a list of a few job titles that require PLC programming experience:

- PLC Technician

- Controls Technician

- PLC Programmer

- Automation Engineer

- Automation Engineer

- Controls Application Engineer

- PLC Specialist

The great thing about PLC programming is that many control technician or PLC specialist jobs do not require a degree in the field. While many PLC jobs are listed above, some engineering roles may require advanced degrees to apply.

Working in automation will give you job stability because you will have many opportunities as the automation and robot industry grows. Many sectors are available for PLC programmers to find jobs.

Contracting at the start of a career is beneficial for gaining a lot of PLC experience. Places like JOINER Services offer controls engineering jobs on their engineering service platform, giving contract PLC programmers or controls engineers many opportunities to see many different client facilities, to build their programming experience quickly.

WATCH THIS FINDING AUTOMATION CLIP

Most popular automation training categories:

Stay Informed

Subscribe to our newsletter and get the latest automation news, trends, and topics in the industry.